CAM Tech, Inc. (262-679-8004) has expanded its facility in Muskego, Wisconsin, to support growing demand for precision die manufacturing.

MUSKEGO, WI, May 03, 2025 /24-7PressRelease/ — With CAM Tech, Inc.’s most recent expansion, they added 6,000 square feet of shop space bringing the company’s equipment total to 13 high-speed Wire EDM machines and two EDM micro hole drilling stations. Thanks to this improved capacity, CAM Tech can accommodate both quick-turnaround orders and larger production contracts.

More details can be found at https://www.camtechedm.com/the-role-of-wire-edm-in-tool-and-die-manufacturing

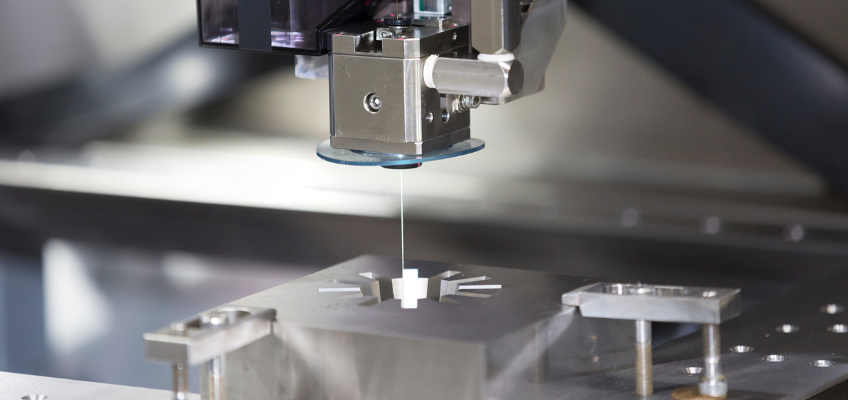

Wire EDM technology plays a key role in die manufacturing by enabling the precise cutting of hardened materials such as steel and carbide. The process facilitates the production of components without stress or distortion and allows for the creation of complex shapes not possible with traditional methods. CAM Tech uses Wire EDM to manufacture compound and progressive stamping dies, trim dies, punches, and buttons.

CAM Tech serves a range of industries requiring high-precision components, including the medical, aerospace, and automotive sectors. The company produces gears, splines, keyways, cutters, and carbide components with exact measurements, and its injection molds help manufacture plastic items from bottle caps to car parts.

“We remain small enough to work closely with our customers, providing quick turnaround while maintaining a high standard of quality,” said a company representative. “However, we are large enough to tackle production and contract jobs, with the ability to run 24/7 to meet customer schedules.”

This business model has earned CAM Tech a five-star rating on Google. One customer noted, “We have been using the services of CAM Tech for a number of years and have always had great quality, on-time completion of our orders. Also, very well priced runs that help us retain our customers.”

About CAM Tech

Founded in 1996 with a single wire EDM machine, CAM Tech brings more than 30 years of Wire EDM experience to tool and die manufacturing. The company supports customers throughout all phases of production, from prototyping to full-scale runs.

To request a free quote on Wire EDM services for die manufacturing, visit https://www.camtechedm.com

—

For the original version of this press release, please visit 24-7PressRelease.com here